Once the printed sheets have been printed and further processed, the individual folding boxes must be precisely die-cut from the sheet. Various technologies are available for this purpose. Depending on the sheet format, number of sheets and material, either conventional die-cutting technologies or innovative laser die-cutting technologies are used.

During the die-cutting process, the shape of the folding box is cut out of the printed sheet. The fold lines/creases are made in the material, and any perforations, windows or embossing are added. Finally, the folding boxes are broken out. This means that the excess material is removed either inline during the die-cutting process or manually afterwards.

Conventional punching / laser punching

There are two main types of punching technology: conventional punching and laser punching. Conventional punching is further divided into flatbed punching and rotary punching. Conventional punching is particularly suitable for large order volumes – the machines are very fast (several thousand sheets per hour) and can also process very large sheet formats. However, these technologies are not suitable for small print runs, as each job incurs varying tooling costs (€200-1000). These depend on the punching technology, the sheet format and the manufacturer. For flatbed die cutting, a so-called strip steel cutting tool is used, which consists of a sturdy wooden board and precisely applied cutting and creasing forms. The production of such a tool takes between 2-4 working days. However, the cost of such a tool is usually a one-off expense.

Unlike conventional punching technologies, the new, high-tech laser punching machines do not incur any tooling costs. High-precision CO₂ lasers are used to laser-cut the folding box shape and create the necessary grooves by removing material. Due to the smaller sheet format (max. 700 x 1000 mm) and the lower machine speed, these laser punches are particularly suitable for small to medium-sized runs. This technology is particularly advantageous when speed is of the essence. Folding boxes can be produced within 2-3 working days.

Grooving / Groove

When creasing folding boxes, a so-called creasing pattern is embossed into the printed sheet. At these points, the material is weakened so that it can later be folded/creased optimally. The creases thus determine the subsequent three-dimensional shape of the folding boxes.

Depending on the punching or laser technology used, a distinction is also made between creasing and grooving. Creasing is a forming process. This involves pressing a creasing die into the material. Grooving is a material removal process. A laser removes material at specific points with high precision, which also weakens the material at these points.

Embossing and debossing / Braille

Embossing or debossing involves highlighting or deepening individual elements on the folding carton in a tactile manner. Common elements for this are patterns, individual illustrations or the company logo. This finishing technique is particularly popular because it gives the folding carton a very special look and stands out, especially at the point of sale.

The corresponding embossing die is incorporated into the punching tool. Depending on the sheet format and the number of copies on it, different numbers of embossing dies are required.

Apart from their use in marketing, embossed lettering is primarily used in the medical sector in the form of Braille.

Perforation

Perforation is less of a finishing touch and more of an extension of the functional properties of folding boxes. Perforations serve, for example, as tamper-evident closures or for separating individual packaging elements such as a viewing window. This eliminates the need for additional tools such as scissors or knives.

The perforation of a folding carton also takes place during the die-cutting process. A perforation is a die-cut line with intermittent breaks. Depending on the material, grammage and application, the intermittent breaks are die-cut at varying intervals.

Perforations are mainly used, for example, in medicine packaging as tamper-evident closures, or in disposable gloves as opening aids.

Viewing window

A viewing window is a punched-out area of the folding box through which the contents of the box can be seen. Such a viewing window is therefore ideal for presenting the product at the point of sale. A viewing window can be punched out in any conceivable shape, such as a square, circle or even special shapes. In addition, a viewing window can be punched out on one side or across several sides. Depending on the size of the viewing window and the contents of the folding box, a viewing window can optionally be backed with a film. This protects the product and ensures that the contents cannot be removed without authorisation.

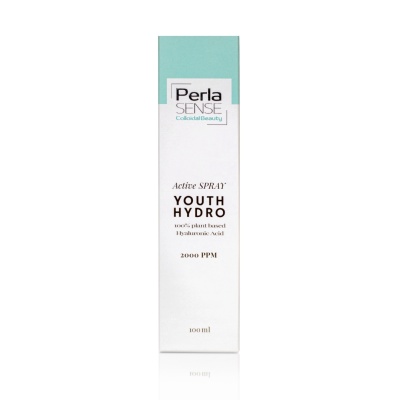

Folding boxes

Folding boxes

Shipping boxes

Shipping boxes

Stand-up pouch

Stand-up pouch

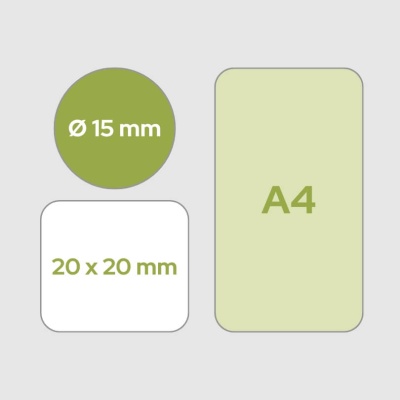

.png) Roll labels

Roll labels

Paper cans

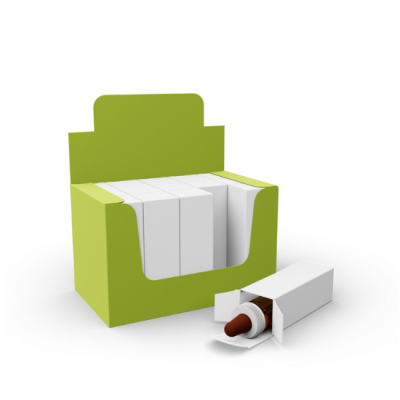

Paper cans  Sample boxes

Sample boxes