Made in Germany

Free Delivery

Highest cardboard quality

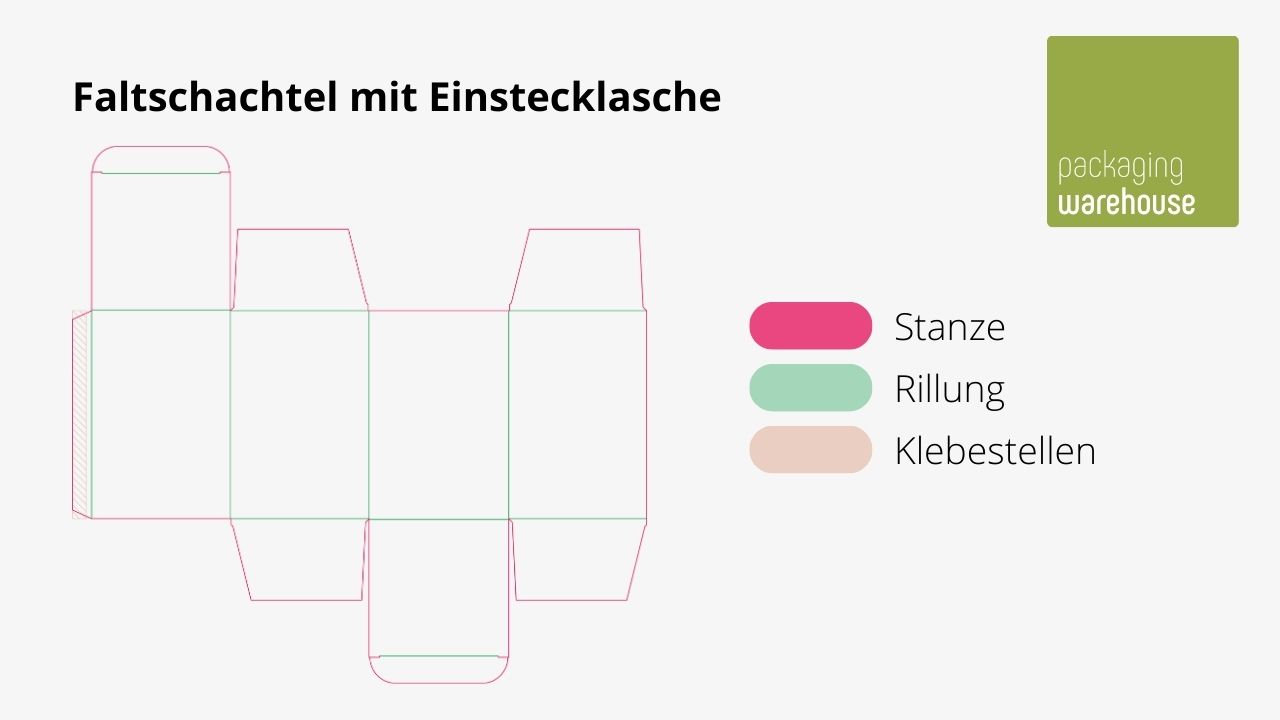

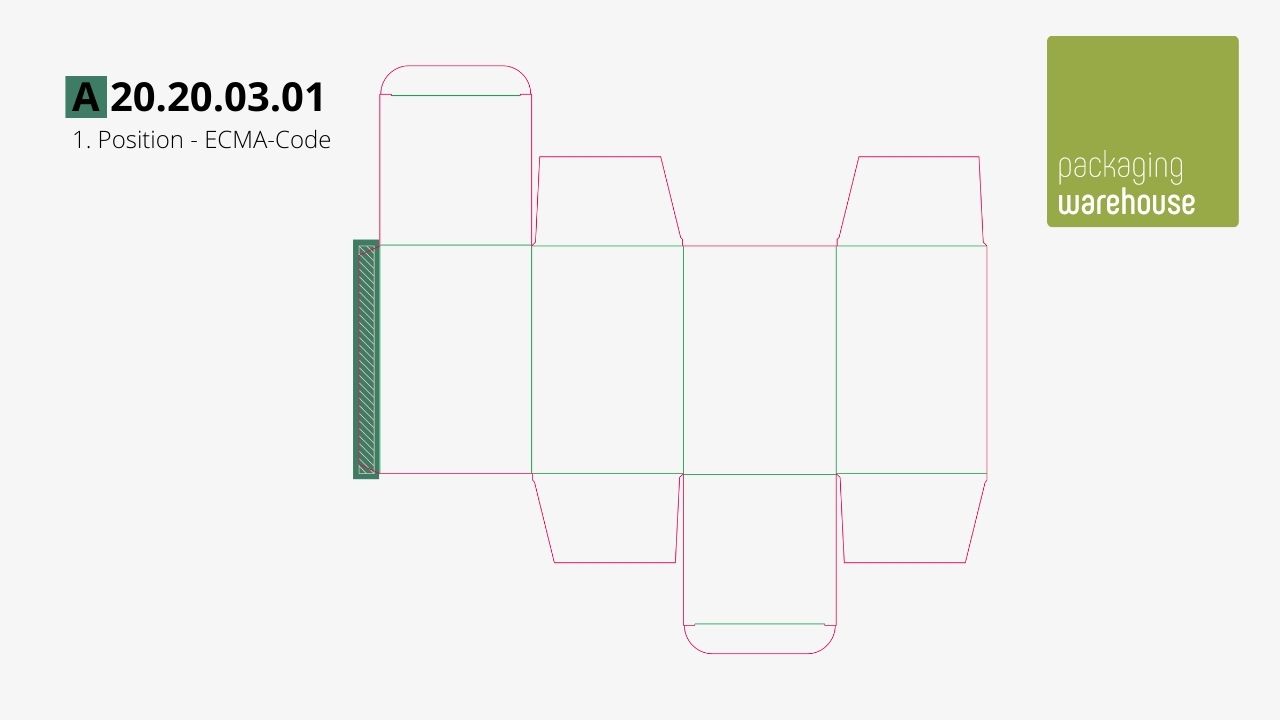

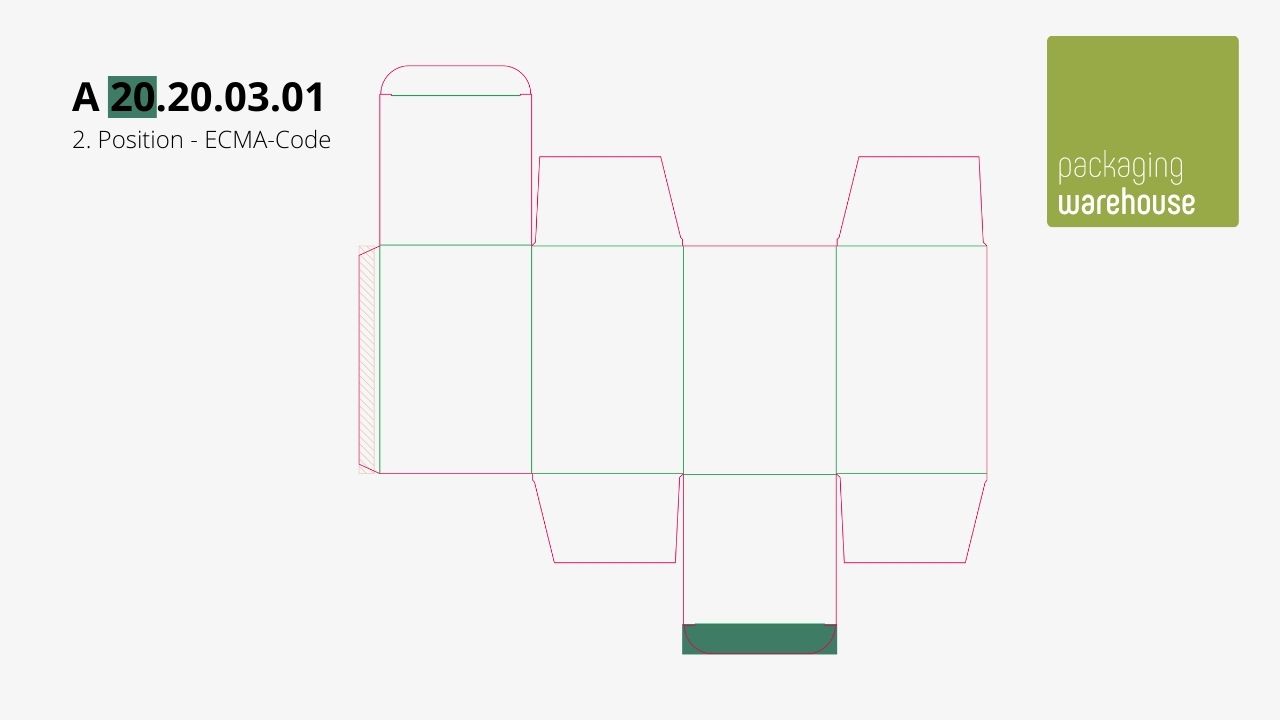

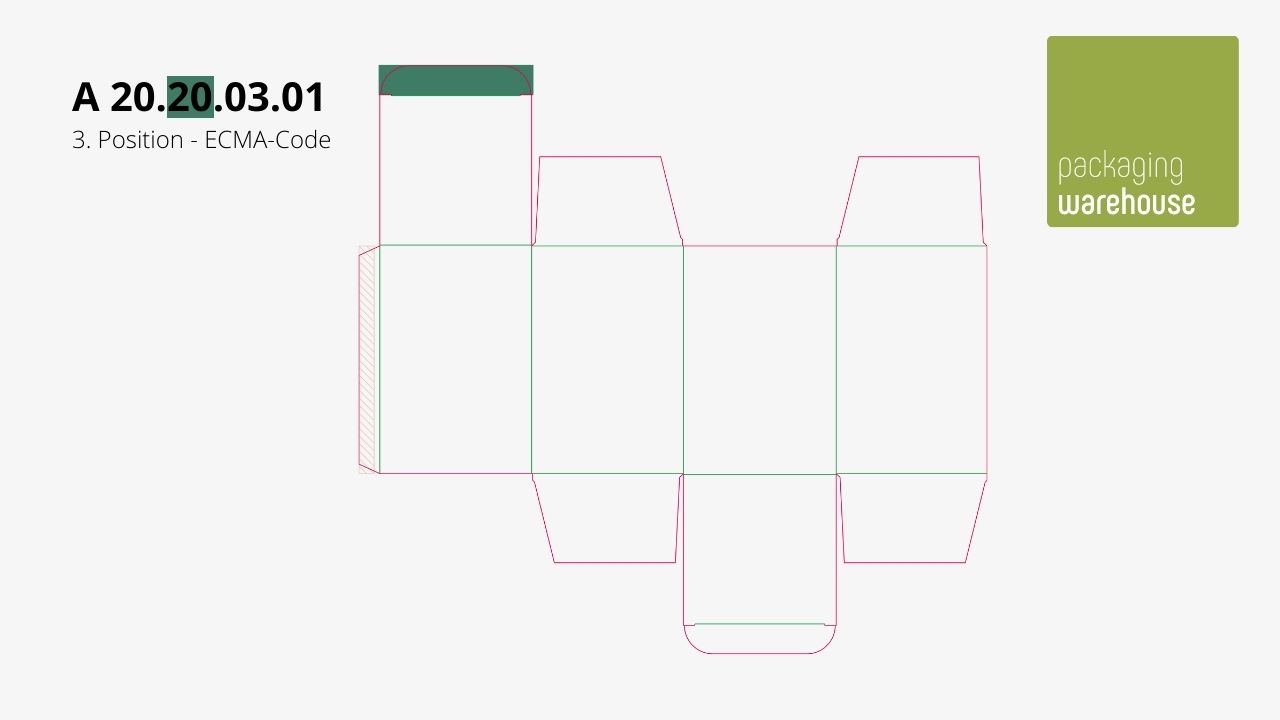

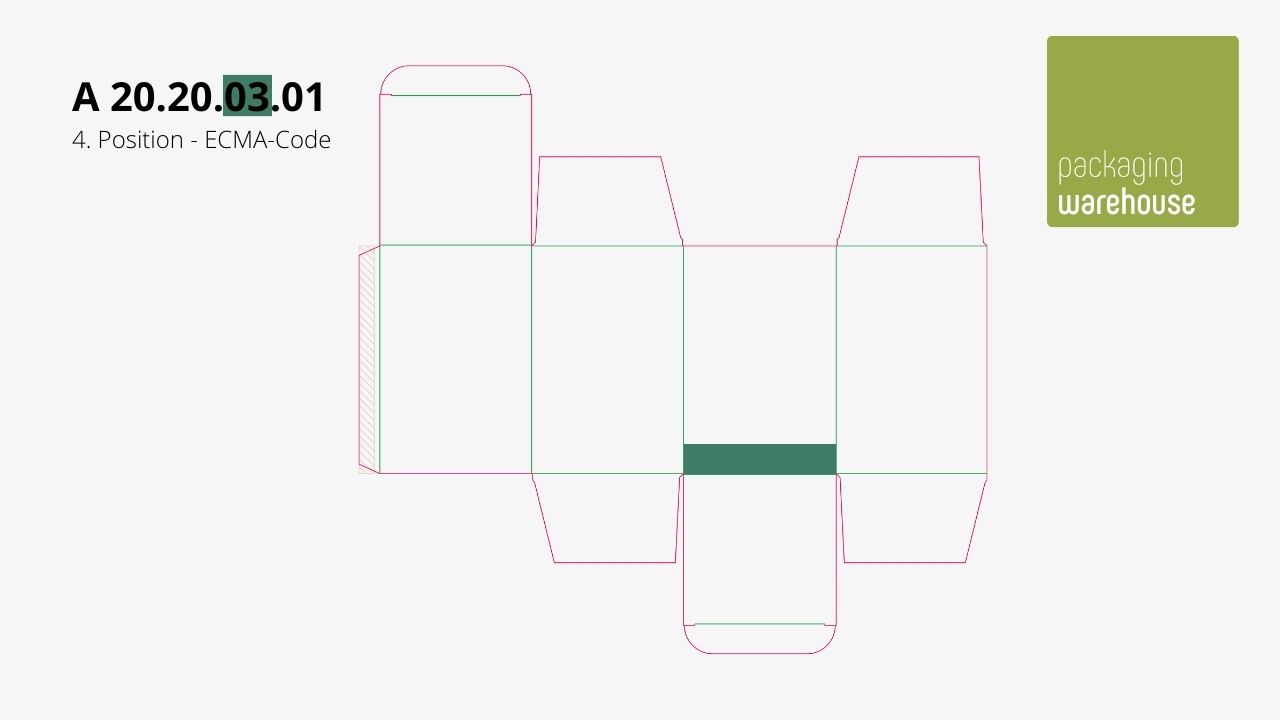

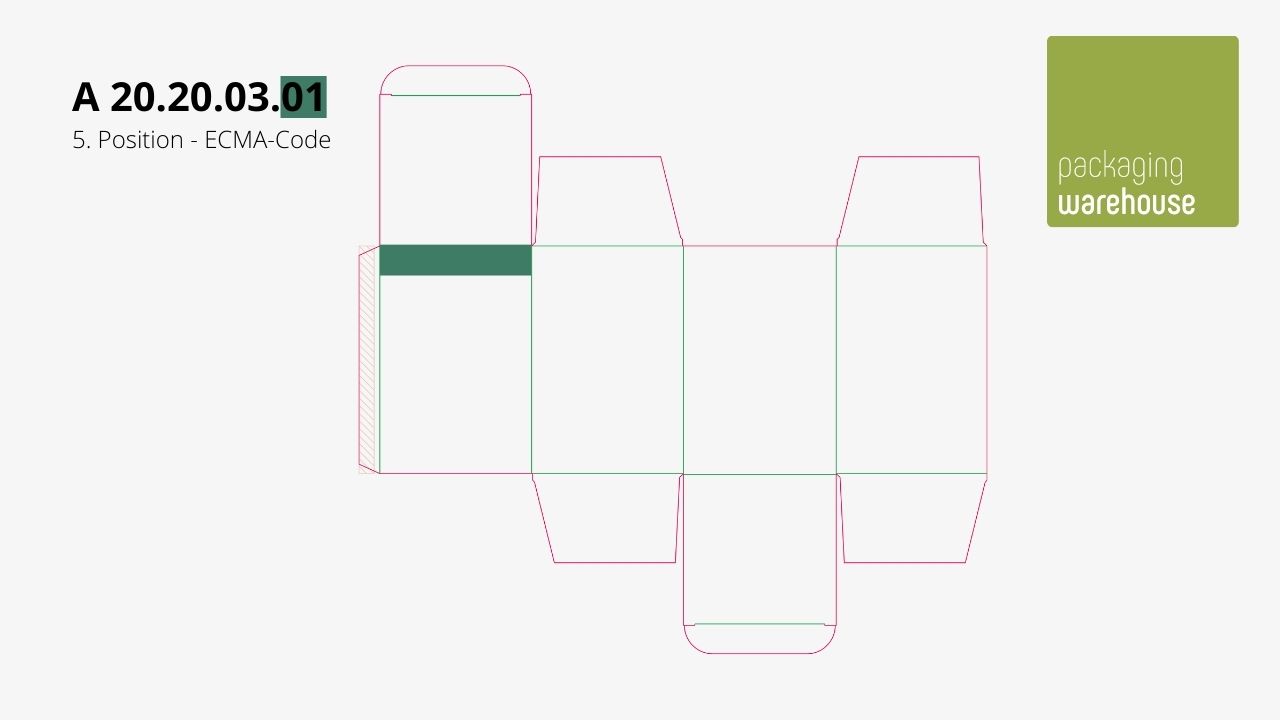

Configure folding boxes with tuck-in flap

Google reviews

INTERESTING FACTS

CONTACT US

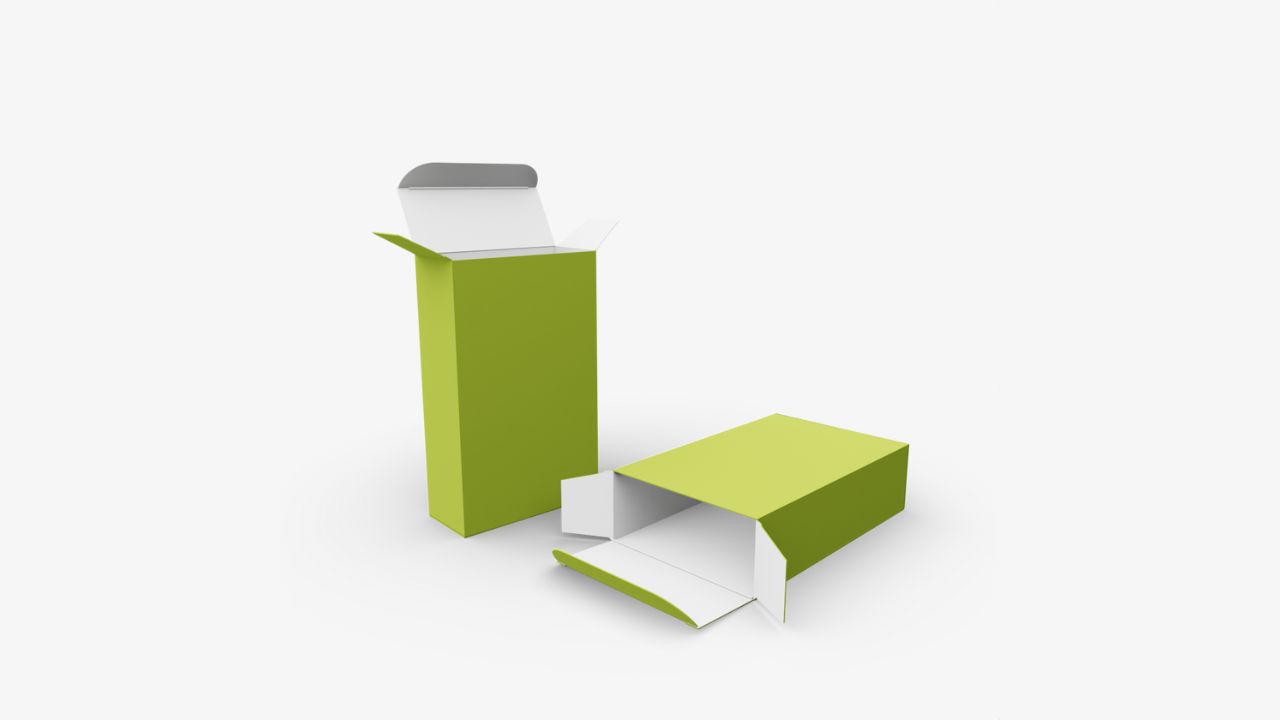

Folding boxes with tuck-in flap directly FROM THE MANUFACTURER

Sustainability and quality are not mutually exclusive. We prove this with our selection of high-quality materials that are not only robust, but also recyclable and compostable.

Our high-quality materials for folding boxes with tuck-in flap:

Our folding boxes with tuck-in flap offer you a wide range of possibilities: